Departments

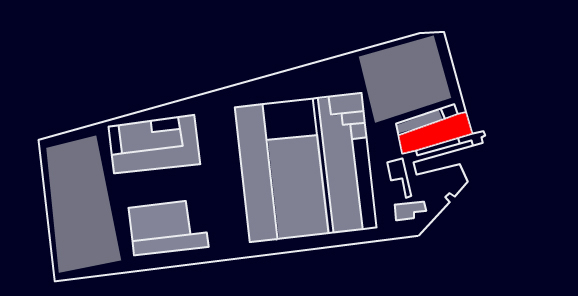

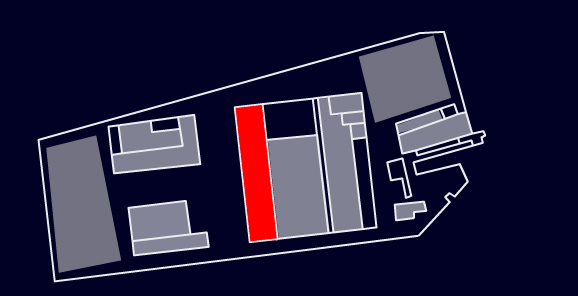

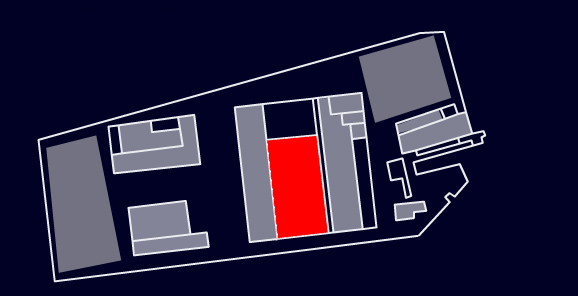

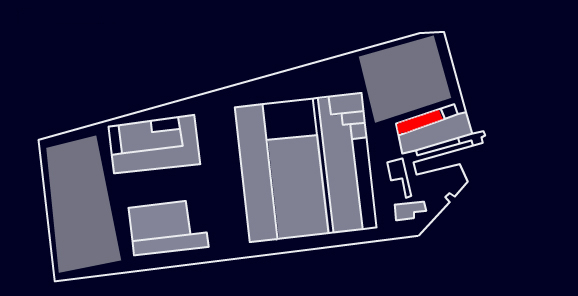

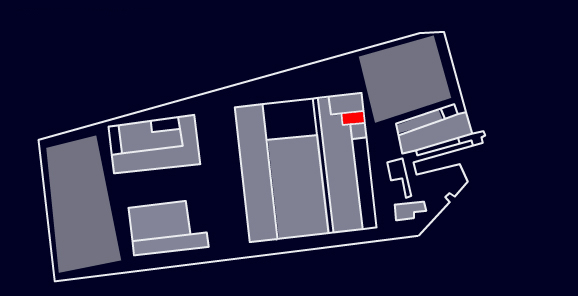

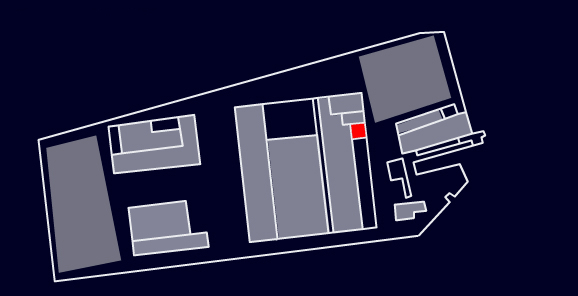

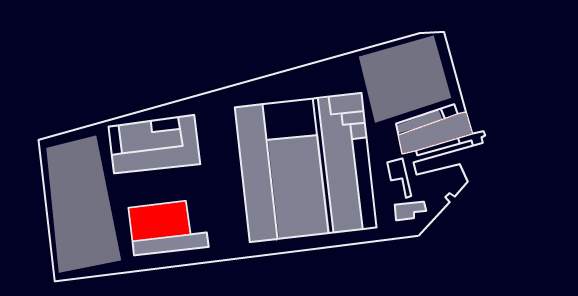

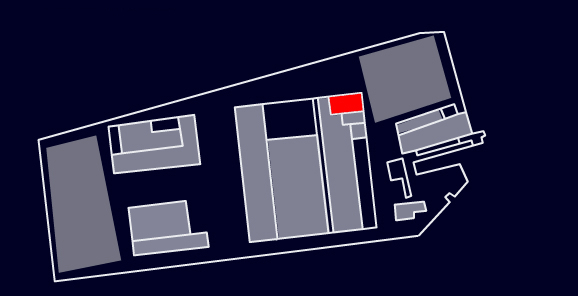

| Prefabrication department |

ACTIVITIES

Cutting, bevelling, cold and hot rolling, forging and pressing bench.

MAIN EQUIPMENT

2 oxygen cutting bench 3500x18000x140mm

2 plasma cutting up to 60 mm of SS plates

2 pipes oxygen cutting up to diam. 60'' and 50mm thk

1 branch cutting machine "Muller type" up to diam. 48''

1 gas furnace 2750x1400x5000mm max. temperature up to 1050 C°

3 rolling machine min.diam. 380mm max.thk. by cold 55mm

4 vertical press up to 650 tons

1 horzontal press 800 tons.

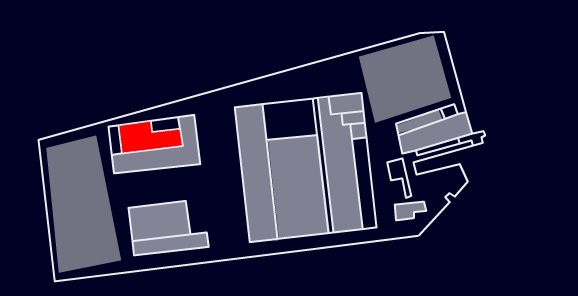

| Cladding department |

ACTIVITIES

Weld overlay is well established technique in SIMAS used to produce pipes and bends able to transport corrosive fluid and gas production streams.

Main corrosion resistance alloys can be overlaid on the main structural backing steels: Ni alloys, stainless steel etc.

MAIN EQUIPMENT

Electro Slag welding (ESW) - n° 3 machines max length 6 m

Gas Metal Arc Welding (GMAW) - n° 3 machines max length 6 m

Hot Wire Gas Tungsten Arc Welding (GTAW) - n° 2 machines max length 12 m

Hot Wire - Gas Tungsten Arc Welding (GTAW) - n° 1 machine max length 6 m

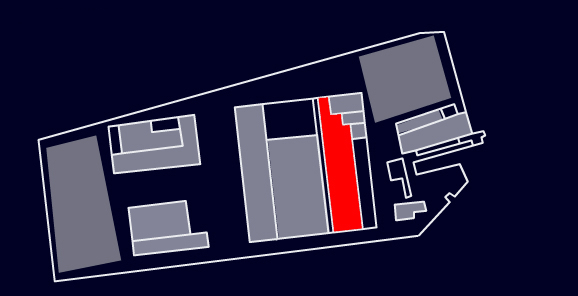

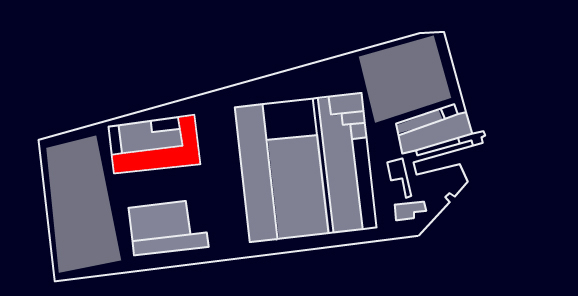

| Assembly department |

ACTIVITIES

Assembly of components, tack welding

MAIN EQUIPMENT

8 turning rolls up to 150 tons

5 turn tables up to 20 tons

8 G.T.A.W. machines

25 S.M.A.W. machines

4 MIG machines

| Welding department |

ACTIVITIES

Welding (GTAW, SMAW, SAW, GMAW) and weld deposit by wire/strip

MAIN EQUIPMENT

8 GTAW machines

25 SMAW machines

6 SAW machines

4 GMAW machines

1 Special SAW machine for nozzles welding (ESAB)

2 Special TIG machines for tube/sheet welding (Hobart/Kotthaus & Busch)

| Clean room with controlled atmosphere department |

ACTIVITIES

All activities requiring an area of 400 m² with temperature and humidity controlled without dust or controlled dust

MAIN EQUIPMENT

1 bridge crane 6 tons

| Heat treatment department |

ACTIVITIES

SIMAS is able to perform the following heat treatment operations using suitable facilities: normalizing, tempering, stress relieving, annealing, quenching & tempering (using our internal water tank dimensions suitable for furnace sizes and with water temperature and circulation constantly controlled), solution annealing

SIMAS can relay on modern and complete equipment available to ensure heat treatment also on large diameter bends with straight tangents on both ends

MAIN EQUIPMENT

1 gas furnace 3400x3000x12800 mm with mobile heart and temperature record up to 1200°C equipped to maintain a uniform temperature inside

1 tank for quenching 2700x8700x3700 mm

1 gas furnace 2000x1200x7500 mm with mobile heart and temperature record up to 1200°C equipped to maintain a uniform temperature inside. Norsok qualified

1 tank for quenching 2100x8250x2000 mm

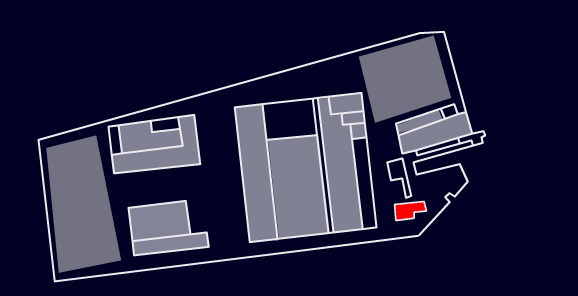

| Hydrostatic and pneumatic test department |

ACTIVITIES

Hydrostatic and pneumatic test of SIMAS production

MAIN EQUIPMENT

2 pumps up to 1300 bar for hydrostatic air pressure up to 5 bar

| Bending department |

ACTIVITIES

Hot induction Bending of seamless and welded pipes

MAIN EQUIPMENT

1 hot induction bending machine diam. from 2'' up to 16'' - radius from 100 mm up to 2800 mm

1 hot induction bending machine diam. from 2'' up to 42'' - radius from 150 mm up to 5300 mm

1 hot induction bending machine diam. from 6'' up to 60'' - radius from 1450 mm up to 10500 mm

| Machining department |

ACTIVITIES

Turning, boring, drilling, beveling

MAIN EQUIPMENT

3 lathes max. diam. 2000 mm / max. length 8000 mm

4 boring machine max. diam. 64''

3 column drilling machines diam. up to 60 mm

2 portable bevelling machines diam. up to 16''

| Quality control department and bunker |

ACTIVITIES

Testing and analysis.

Our non-destructive-examination personnel is certified as Level II SNT-TC-1A and EN 473 by Company Level II and or by Authorized Third Party is able to perform:

- Penetrant test method;

- Magnetic particle test method;

- Ultrasonic test method;

- Radiographic test method;

- Positive material identification (PMI);

- Hardness test by Poldi or Equotip or calibrated pins portable instruments;

SIMAS can rely on an external independent accredited laboratory equipped to perform the mechanical test of:

- Brinell Hardness Testing;

- Tensile Testing 150 tons universal tensile and compression testing machine;

- Hardness testing HV, BHN, HRC, HRB etc. including microhardness;

- Impact Test CHARPY and IZOD equipment: H.I.C. - S.S.C. - C.T.O.D. - D.W.T:T.

MAIN EQUIPMENT

3 X-rays machines

2 Gamma rays machines

2 Krautkramer Equip. for U.T.

2 Gilardoni Equip. for U.T.

2 portable Yoke for M.T.

1 portable equipment for hardness (Equotip)

1 positive material analyzer (Spectrotest TX C01).

| Shotblasting department |

ACTIVITIES

Shotblasting of SIMAS Production

MAIN EQUIPMENT

1 automatic shotblasting machine for pipes and bends up to 30'' OD - up to SA 3.5 surface roughness

| Packing department |

ACTIVITIES

Packing, marking and conditioning of SIMAS products before shipment

MAIN EQUIPMENT

Fork lift, cranes, other suitable tools.

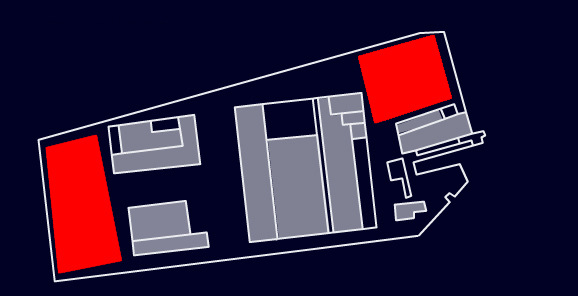

| Office department |

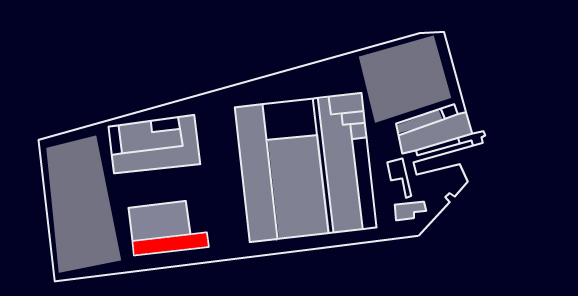

Offices area: 1000 square meters

| Storage department |

Storage area: 29,000 square meters

Websites of the Group

SIMAS S.R.L. - Sede legale / Registered office: Via Luigi Bassi 8, 26865 San Rocco al Porto, Lodi, Italy

Capitale sociale / Paid capital € 1,000,000 - Camera di Commercio / Chamber of Commerce: LO 1476174 - IVA / VAT No. IT 10916000150

Privacy policy - Credits